Hot Plate EMS 1000-3

Description

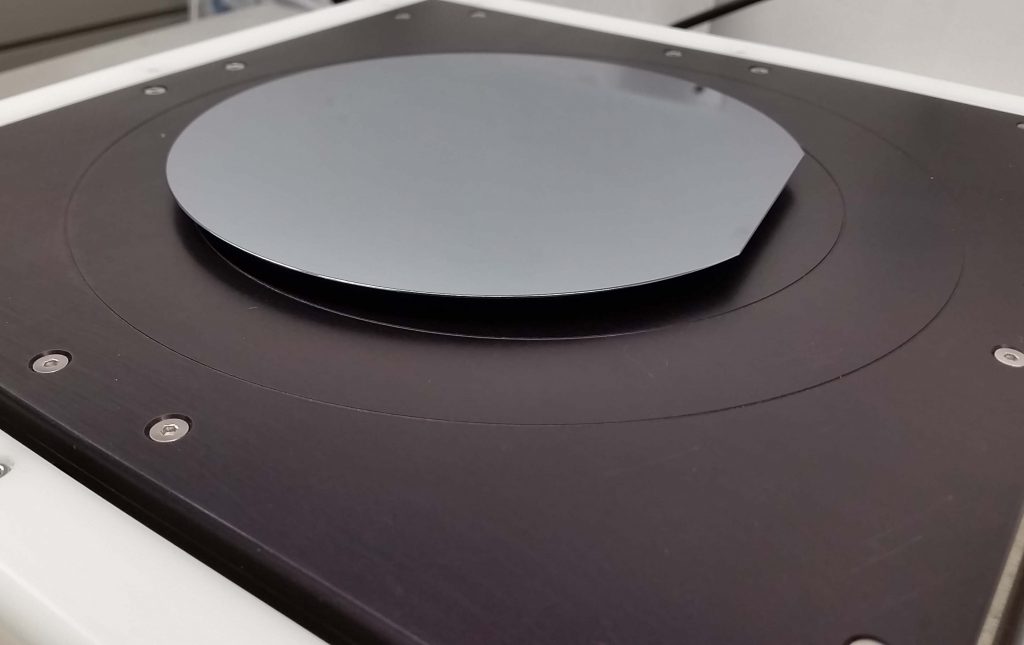

The EMS 1000-3 provides all of the features, and capability of the EMS 1000-1, with added feature of Lift Pins.

The Lift pins are centered on a radius of 20mm, and allow easy loading and unloading of larger substrates with a vacuum wand.

The lift pins and vacuum will always be synchronised to ensure smooth loading and unloading.

Four Lift Pins on a 20mm radius

Four Lift Pins on a 20mm radius Up position for loading and unloading

Up position for loading and unloadingConfiguration Options

Steady State Temperature

- With Hot plate set to the desired temperature, there is an option to program the time the Lift Pins and vacuum are down / On. With the start initiated by a momentary button switch labeled vacuum.

- Or Lift Pins / Vacuum can be initiated Manually via a Latch Button Switch, labeled vacuum.

Ramp and Dwell Heat Cycle

- With the PID controller set up to run Ramp and Dwell, the timing capability of the controller is already used, so there is is only one option to control the Lift Pin / vacuum, that is Manually via a Latch Button Switch, labeled vacuum.

- The Start Ramp and Dwell heat cycle will be via another Button Switch, labeled RUN.

Front Panel

Front Panel

Stress Relief using Lift Pins

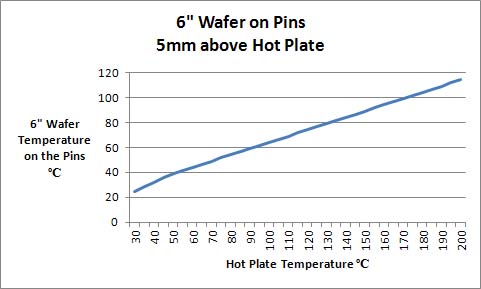

With thicker Photoresist films comes the potential problems of Stress and Bubbles in the film. A possible technique to allow the solvent in the film to completely evaporate before applying the bake temperature is to place the wafer on the Pins and wait for a period of time, which will allow the wafer to heat up gradually to minimize heat shock as well as improve solvent evaporation. The pins allow the wafer to sit approximately 5mm above the hot Plate surface. The graph below shows the steady state values possible, depending on the Hot Plate steady state temperature.

Steady State Temp of Wafer on Lift Pins

Steady State Temp of Wafer on Lift Pins Az 4500 Example

The Az 4500 positive photoresist is designed for film thicknesses above 3 µm, it has a prebake heat cycle of approx 110°C for 60 seconds, however it is important to be sure all the solvent is evaporated before this prebake.

So a possible solution is to set up Hot Plate to be steady state at 110°C, set the timer on the Vacuum / Lift pins to be 60 sec. Place wafer on to lift pins wait for about 5 minutes, hit Vacuum button switch, the pins lower and heat cycle is applied as per the red line below. This is a very precise and repeatable heat cycle.