Hot Plate EMS 1000-1

The EMS Precision Electronic Hot Plates provides an extremely accurate even temperatures across the Top surface. This is achieved by mounting heating elements into a Aluminium plate up to 22mm thick. Tooling plate is used to provide a fine homogeneous grain structure, best for precision machining, flat surface and a very stable material with temperature changes. The aluminium is also anodized to provide an excellent inert smooth durable surface, that will not contaminate your samples.

The Hot Plate comes with a sophisticated PID temperature controller, that provides the versatility to meet the most demanding applications, yet simple to use and visually appealing and competitively priced.

- Accurate to ±1% across working surface

- Substrate size from 10 mm to 150 mm

- Temperatures: Basic Model 50°C to 200°C, HT version 50°C to 250°C

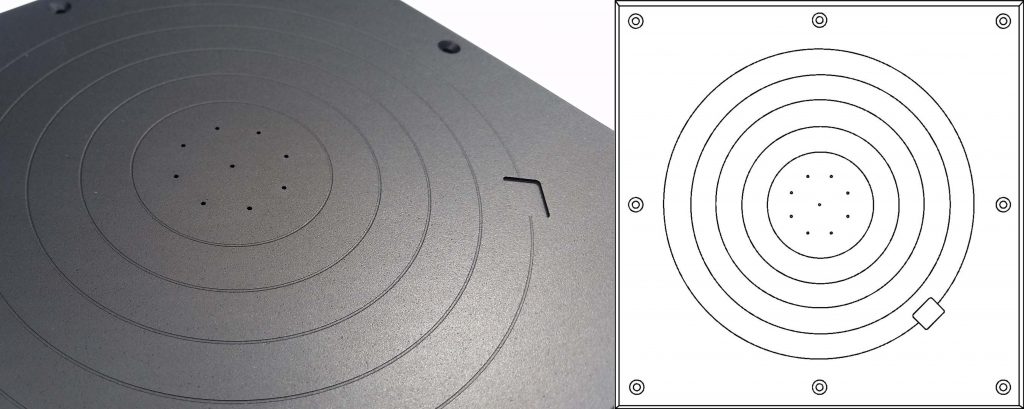

- Vacuum ports to ensure intimate contact between substrate and hot plate (Vacuum holes on a radius of 15mm)

- Tough durable stainless steel casing, easy cleaning.

- Hard Anodised Aluminium Top surface. Tough durable flat surface.

- PID Temperature Controller with digital readout

- High visibility 4 digit LED display shows temperature in °C or °F.

- Delrin Safety Guard, will also minimize heat loss at the outer edges.

- Top Plate 200mm x 200mm, System size 350mm x 270mm x 120mm

Standard Features

Configuration Options

- Vacuum Port controlled with a timer in the PID controller and started with a momentary switch. OR Manually controlled with a latch switch.

- Top surface has One small recess (tweezer Pocket) to allow tweezer loading and unloading, this will be on the 150mm scribed wafer circumference OR Totally flat Top surface, OR Customised as you prefer ?

- PID controller configured to Run Heat cycle of 2 Ramps and 2 Dwells.

OR Steady State continuous single set point temperature.

Top Plate with vacuum holes and single Tweezer pocket

Top Plate with vacuum holes and single Tweezer pocket

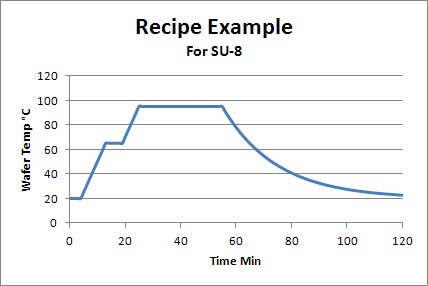

Hot Plate Ramp and Dwell Option

2 Zone Ramp and Dwell Example

2 Zone Ramp and Dwell Example

The standard PID controller allows up to 2 time zones in the recipe, for each time zone we need to tell the controller the values we would like to control to, Temperature, Ramp and Time.

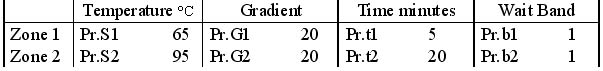

- Pr.Sn* Temperature Set Point of the first Dwell, values 50 to 200°C

- Pr.Gn* Gradient in °C/min, max achievable is about 20°C/min

- Pr.tn* Time of n* Dwell, values 0 to 99 minutes

- Pr.bn* Wait Band of n* Dwell, values 0 to 99°C

(n* is the zone number, up to four zones are possible)

Values required for the example above

Values required for the example above

Upgrade Options

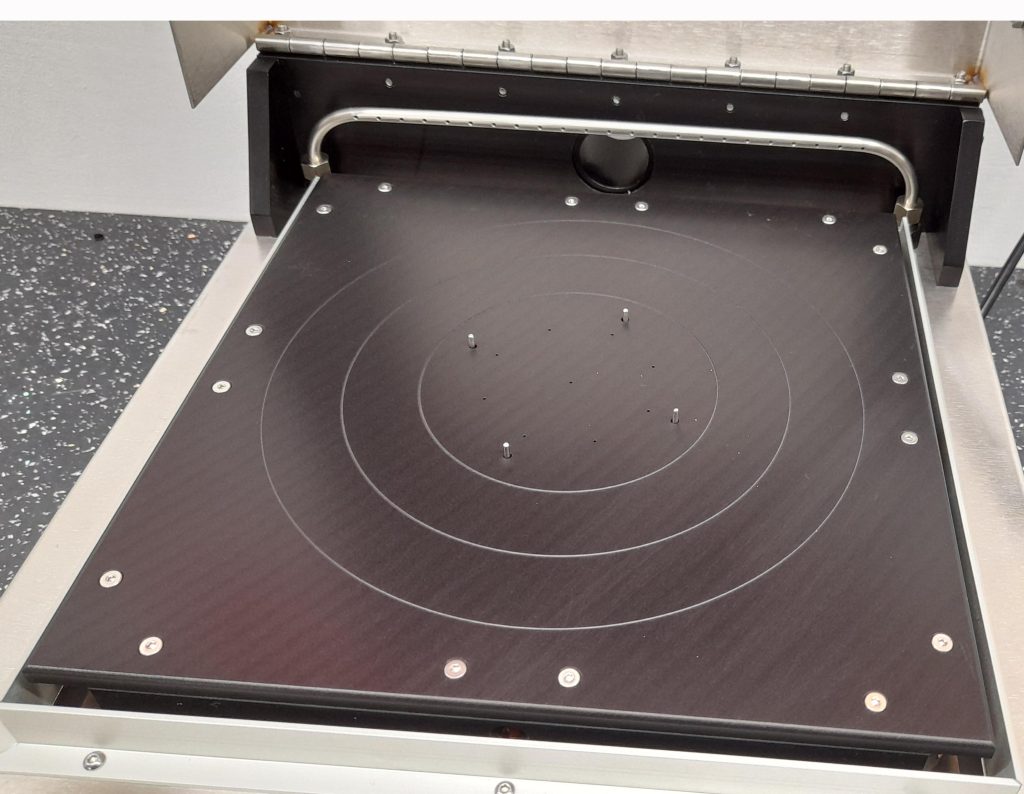

- Added Lift Pins Hot Plate Model 1000-3

- PID controller configured to Run a heat cycle of up to 4 Ramps and 4 Dwells.

- Increased Maximum Temperature capability up to 250°C Hot Plate Options

- Stainless Steel Lid Hot Plate Options

- Nitrogen Purge Hot Plate Options

- Larger System available EMS 1200, Top Plate size of 250mm x 250mm, System size 330mm x 410mm x 150mm. Could be used for small batch processing, or 200mm wafers or square substrates.

EMS 1200-3 with Lid and Nitrogen Purge

EMS 1200-3 with Lid and Nitrogen Purge

Special Round EMS 1000-1

Customised systems for holding a 150mm wafer, with three edge holding points, tweezer pocket and removable pins at the flat to ensure easy removal, plus alarm sound when timer has finished.